MSB3 XX/XX

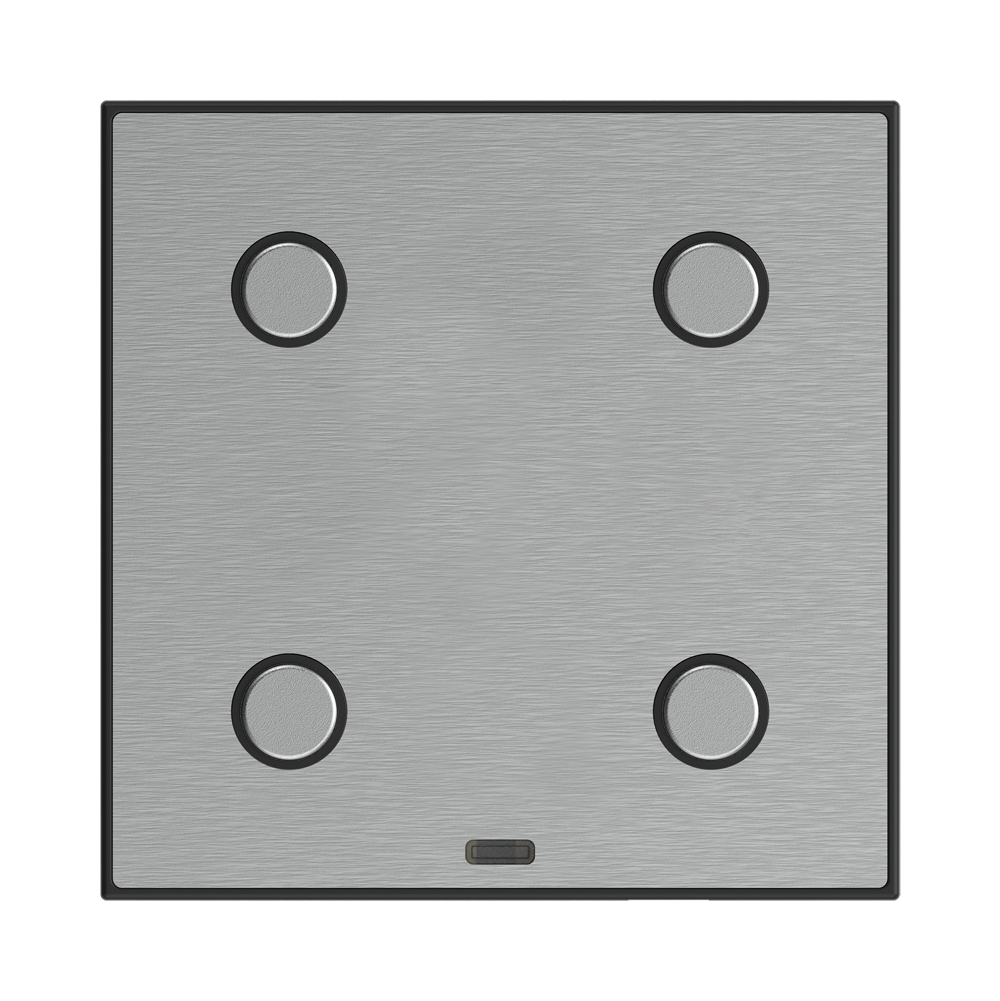

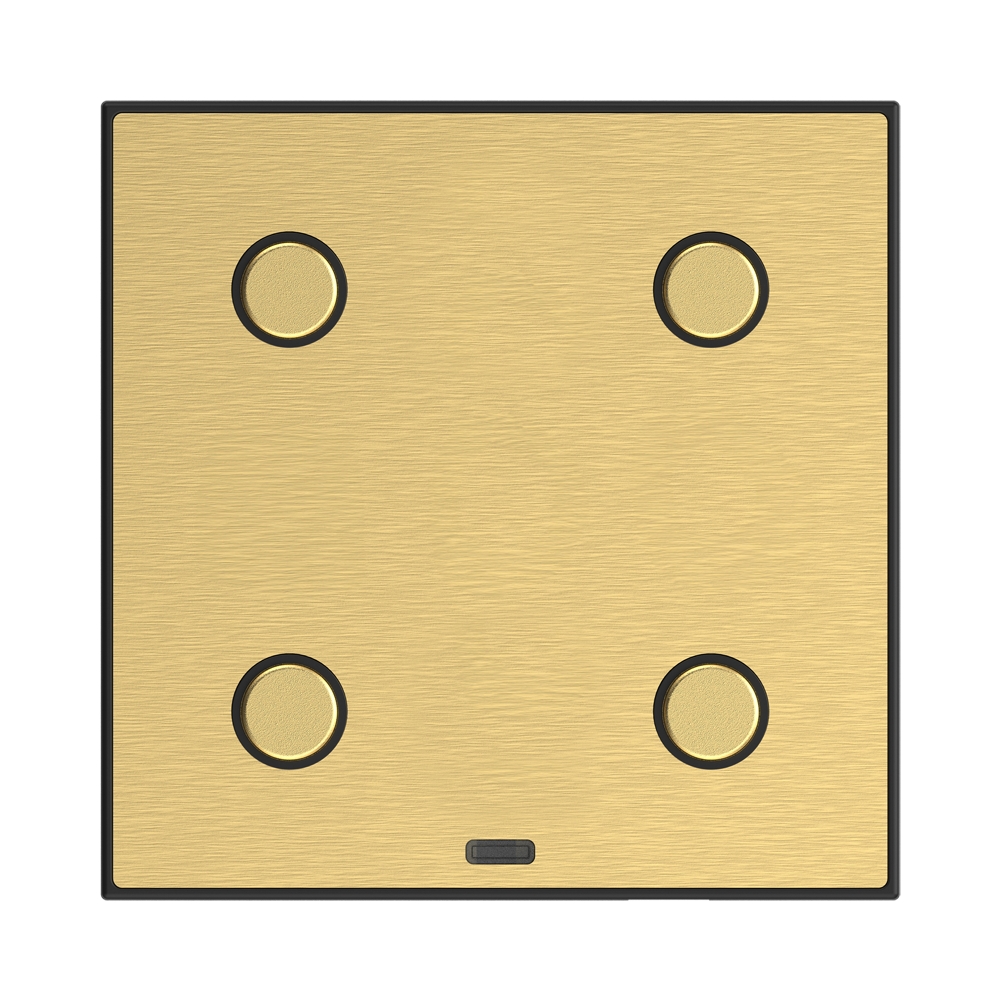

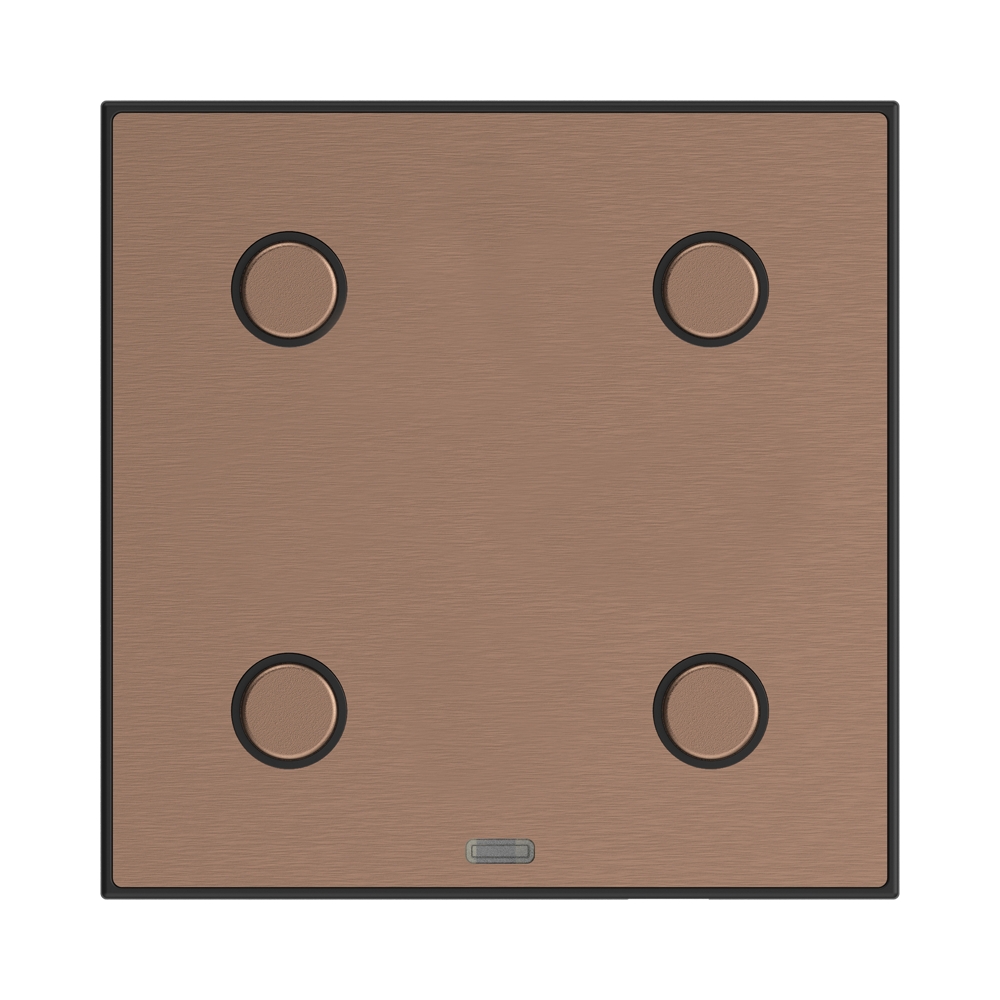

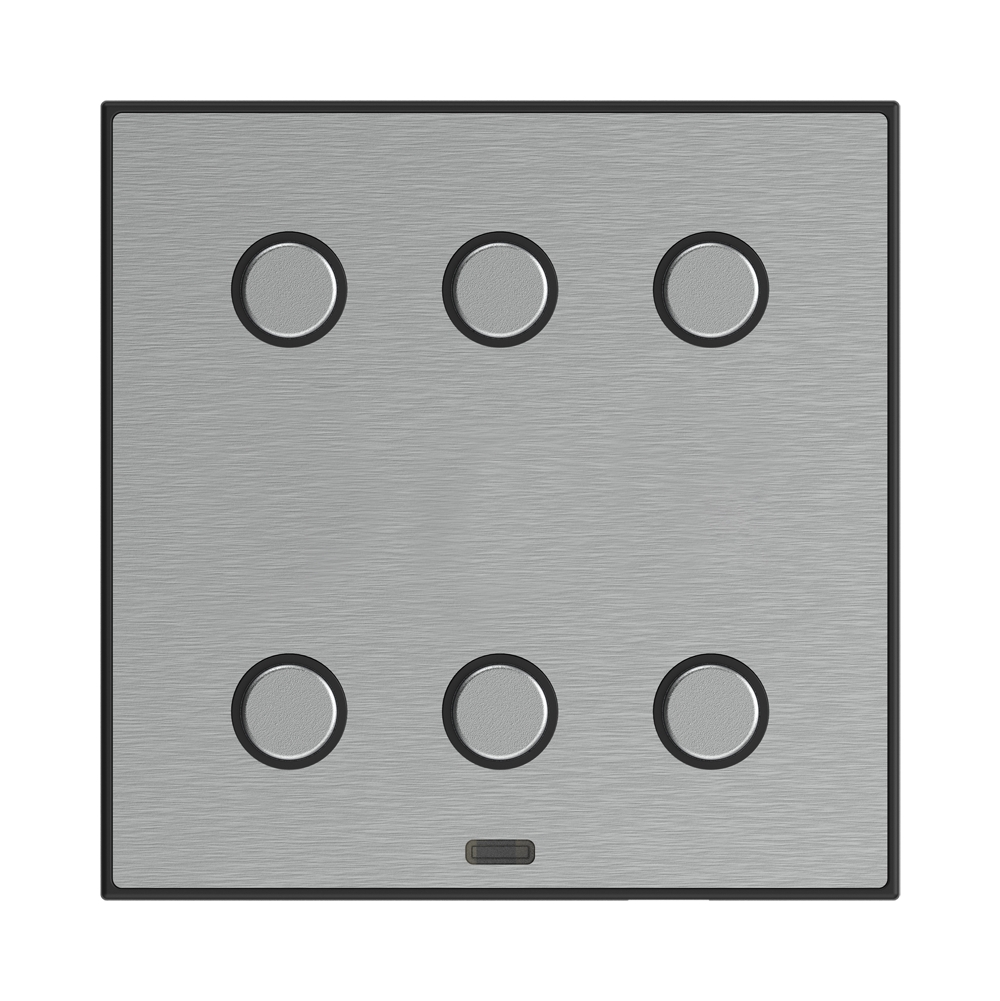

Metal Switch Button

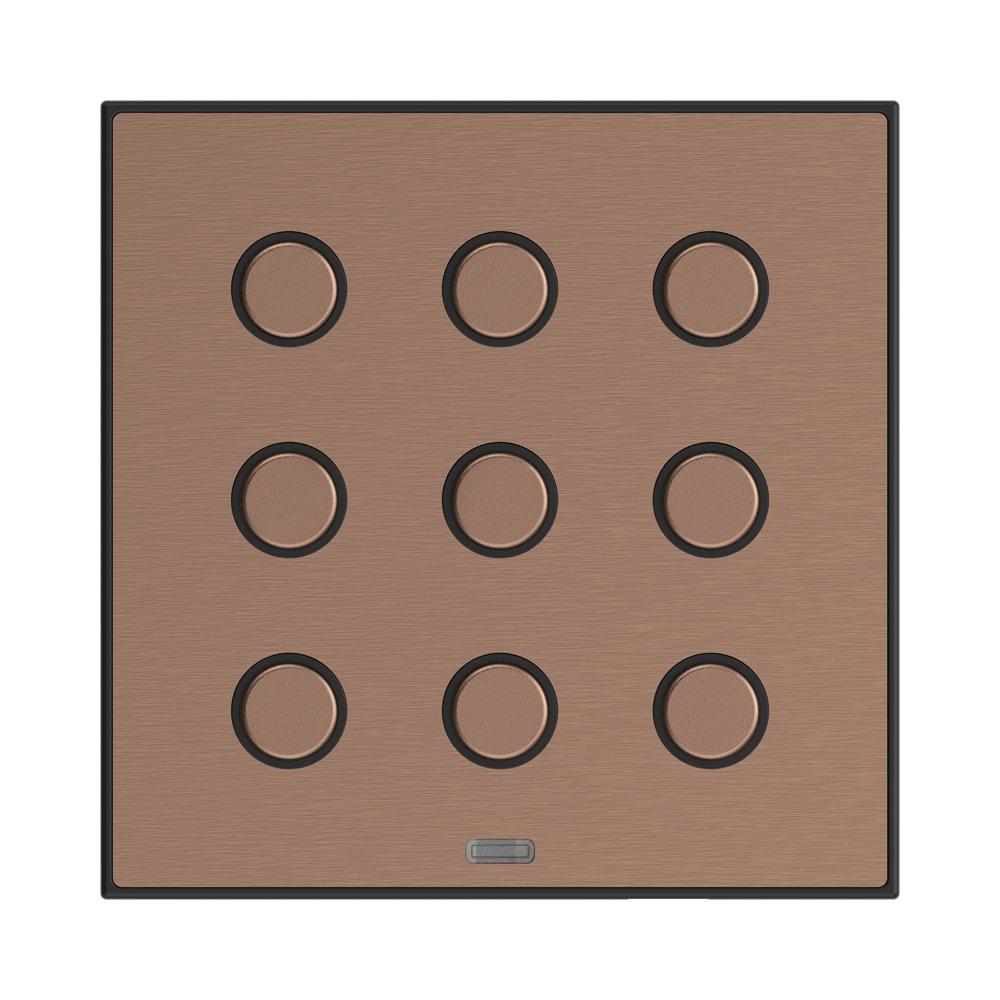

MSB3-40/XX, MSB3-60/XX, MSB3-90/XX

MSB3- XX/BB = Graphite black plate + Graphite black button

MSB3- XX/GG = Satin brass plate + Satin Brass button

MSB3- XX/SS = Brushed silver plate + Brushed silver button

MSB3- XX/CC = Antique copper plate + Antique copper button

Overview of devices

iNELS Metal Switch Buttons (MSB3) offer a versatile and premium control solution for a wide range of projects. Available in MSB3-40/XX, MSB3-60/XX, and MSB3-90/XX variants, these buttons feature premium metal plates in antique copper, satin brass, brushed silver, and graphite black finishes.

MSB3-40/XX

Wall-mounted metal touch controls, 4-button, built-in temperature sensor, 1x temperature input, 1x digital input.

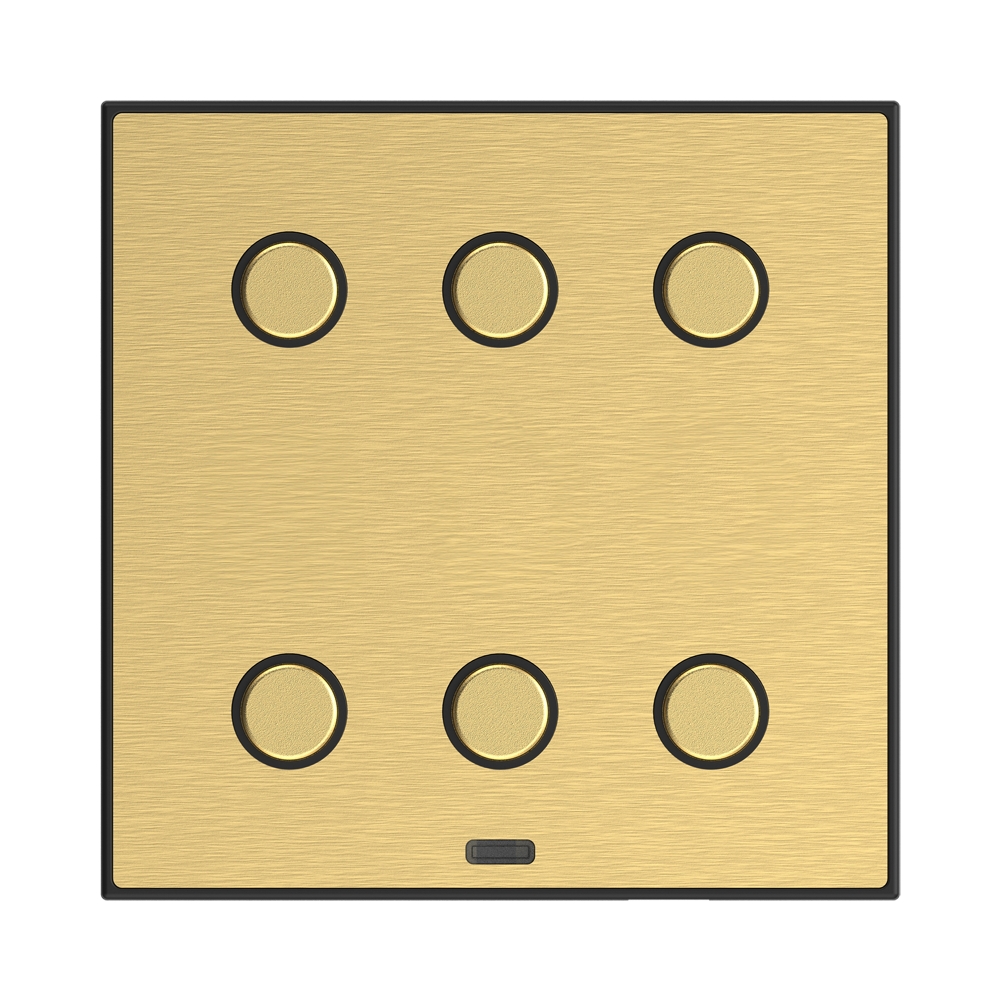

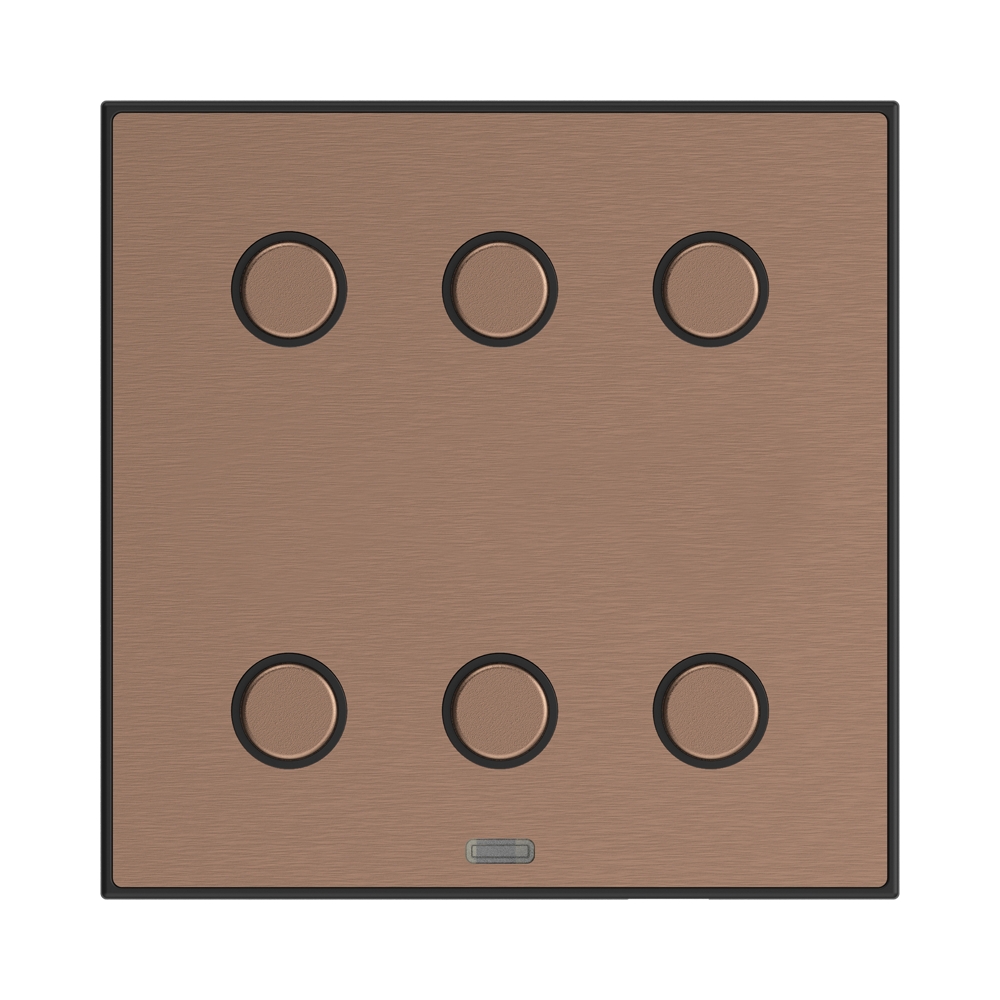

MSB3-60/XX

Wall-mounted metal touch controls, 6-button, built-in temperature sensor, 1x temperature input, 1x digital input.

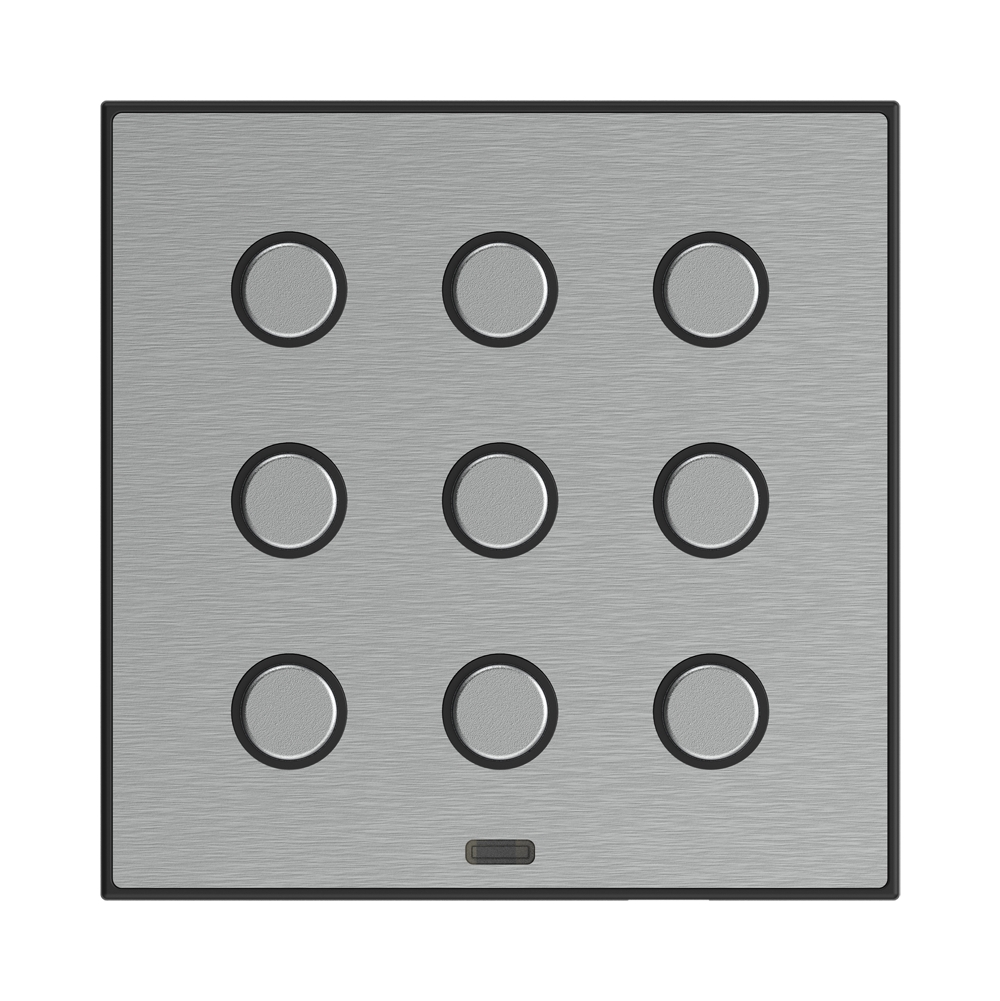

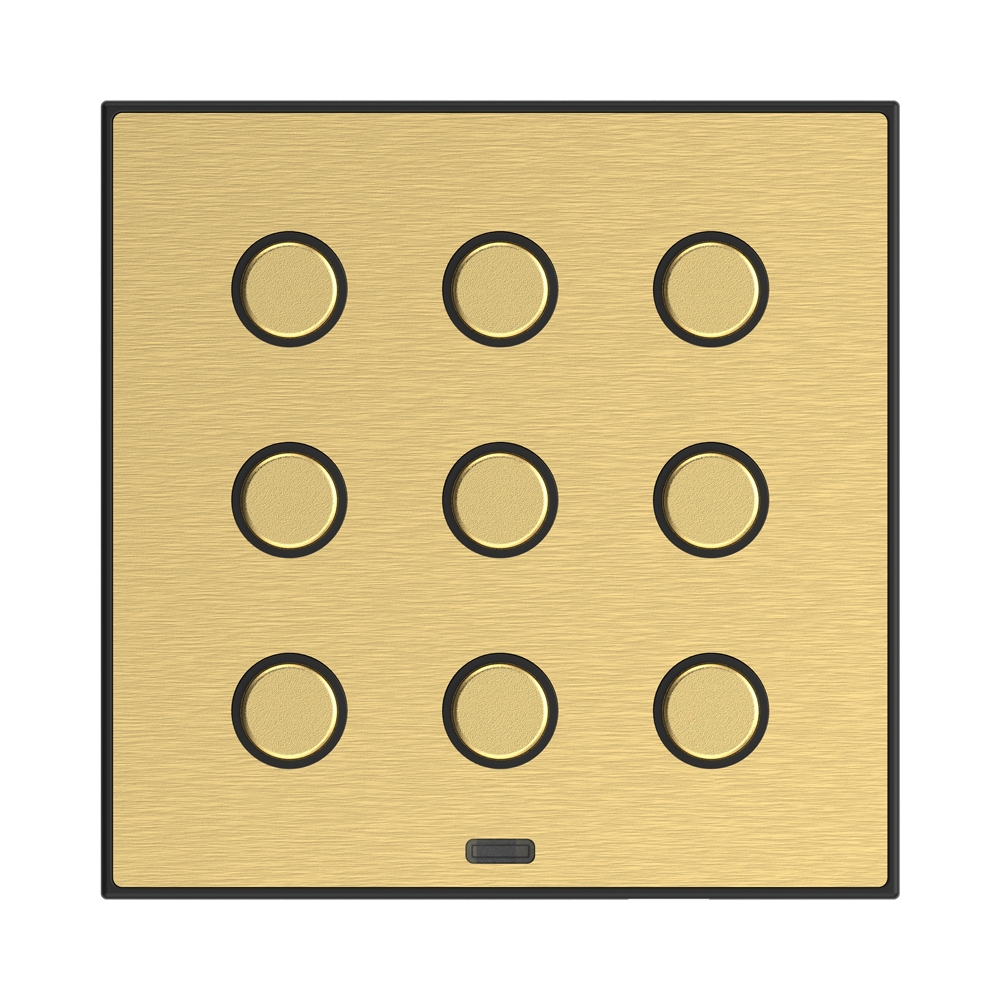

MSB3-90/XX

Wall-mounted metal touch controls, 9-button, built-in temperature sensor, 1x temperature input, 1x digital input.

Key Features:

Variety of Buttons: MSB3 comes in three variants:

MSB3-40/XX: Equipped with four touch buttons.

MSB3-60/XX: Equipped with six touch buttons.

MSB3-90/XX: Equipped with nine touch buttons.

Premium Metal Plates: The switch buttons feature premium metal plates available in antique copper, satin brass, brushed silver, and graphite black finishes.

Customizable Functions: The functions of each button can be easily modified using software.

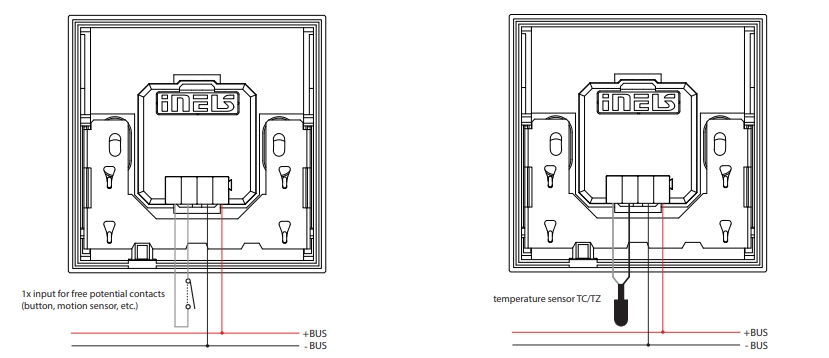

Integrated Sensors: The buttons are equipped with integrated temperature sensors and analog-to-digital inputs (AIN/DIN), allowing connection to potential-free contacts or external temperature sensors for various applications such as floor temperature measurement.

Advantages Over Conventional Switches/Buttons:

Space-saving design

Signaling the state of system outputs

Temperature measurement capability

Ability to connect external buttons or detectors

Versatile Control: Each button can control any actuator (appliance) in the system and can be assigned different functions or macros (set of function), enabling control of multiple appliances simultaneously with a single button.

Design Component of iNELS System: The metal switch button is a design component of the iNELS system, available in antique copper, satin brass, brushed silver, and graphite black versions.

Customization Options: Engraving text for each button is available upon request, enhancing customization possibilities.

Illumination: Individual buttons can be illuminated in white.

Mounting: Designed for mounting into an installation box, all versions are in the size of the standard module (94x94 mm).

Exemplary circuit diagram/ Wiring Diagram

Compatibility chart ( CU, minimal FW version and Integration)

The chart illustrates the compatibility between metal switchboards and various central units, firmware versions, and integration options.

1

CU3-01M

02.9C.00

NA

NA

2

CU3-02M

02.9C.00

NA

NA

3

CU3-07M

02.9C.00

Yes

Yes

4

CU3-08M

02.9C.00

Yes

Yes

6

CU3-09M

Preparation

Preparation

Preparation

7

CU3-10M

Preparation

Preparation

Preparation

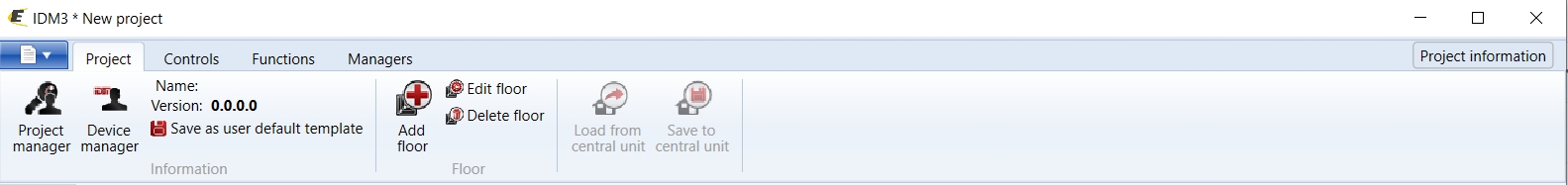

Programming in iDM(Parameters, Functions and logic)

Introduction

iNELS Design Manager, or IDM3, is for programming iNELS units. This software serves as the platform for configuring device parameters, defining functions, and executing the programming required for iNELS units.

Device parameters, such as sensor range and thresholds, backlights, and operational modes, can be easily adjusted within the IDM3.

The process of programming in IDM3 typically involves defining functions and establishing logical connections between different devices. This allows for the creation of automation scenarios and the implementation of intelligent control strategies.

Starting up

Select the "blue control icon" as shown in Fig 1 > Clicking on the option "New project from default template“ allows you to create a new project from a predefined template.

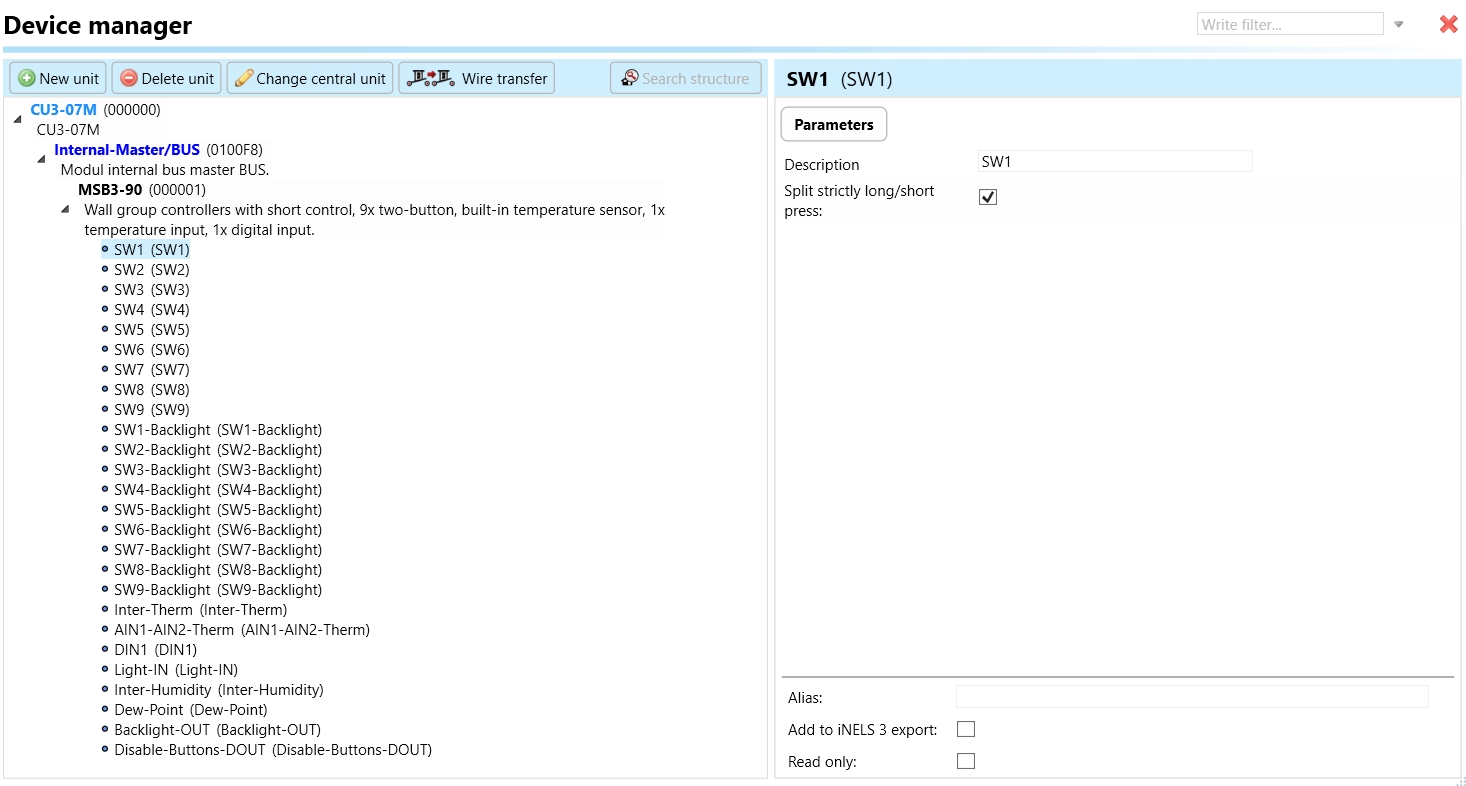

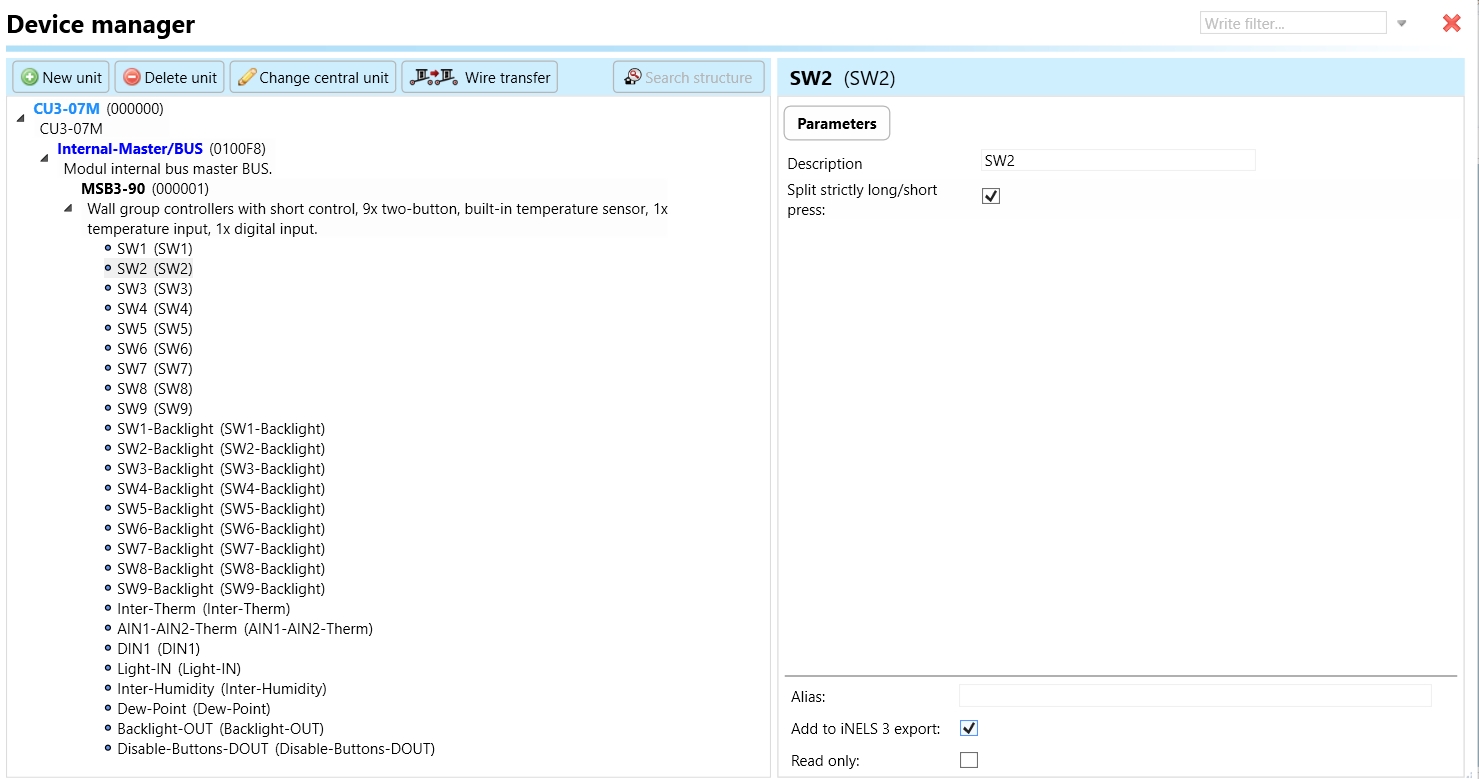

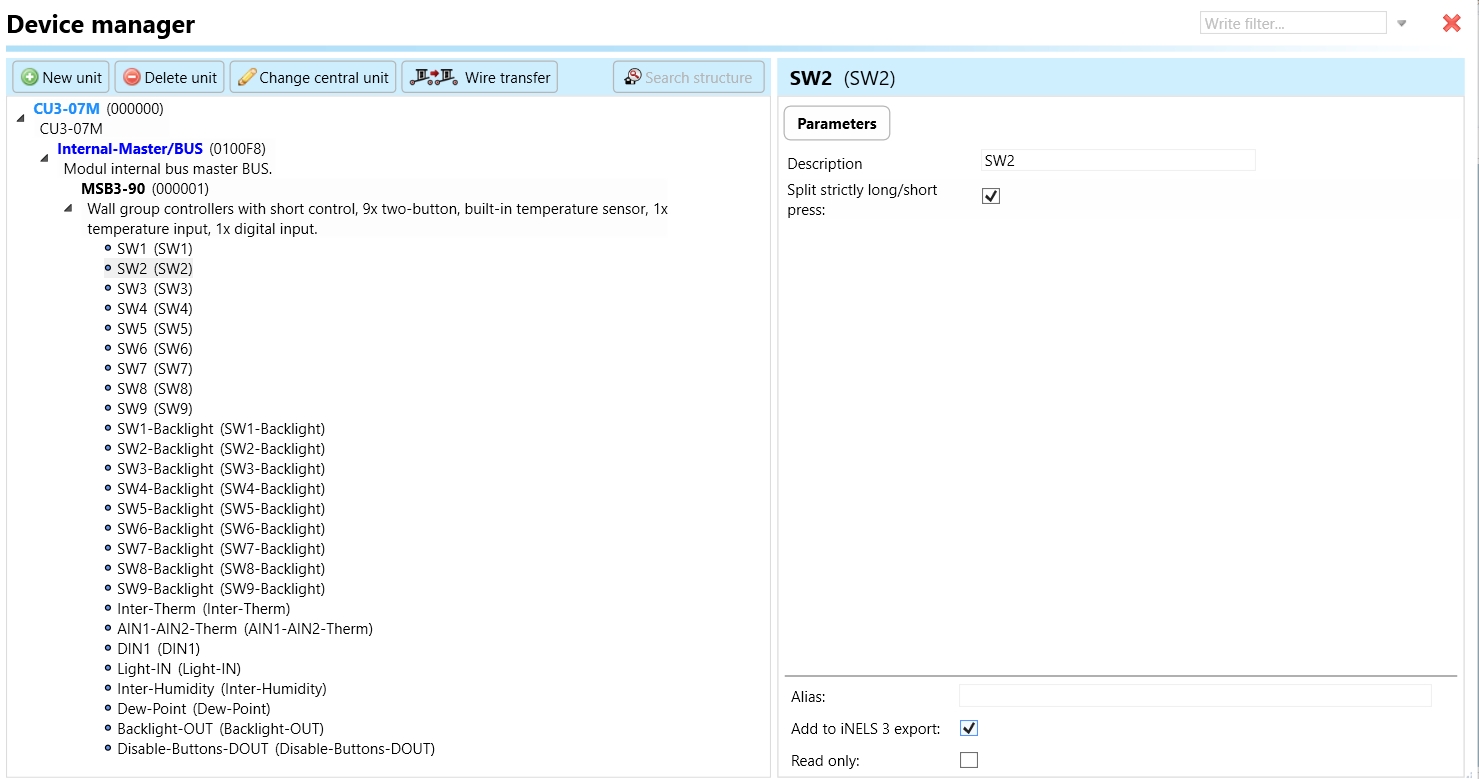

Select the "Device manager" (Fig 1)> Add "New unit "> Select the central unit > Add "New unit">Select the "Internal-Master/ BUS"> Add "New unit "> Add the devices> Click on the devices to see the "Parameters".

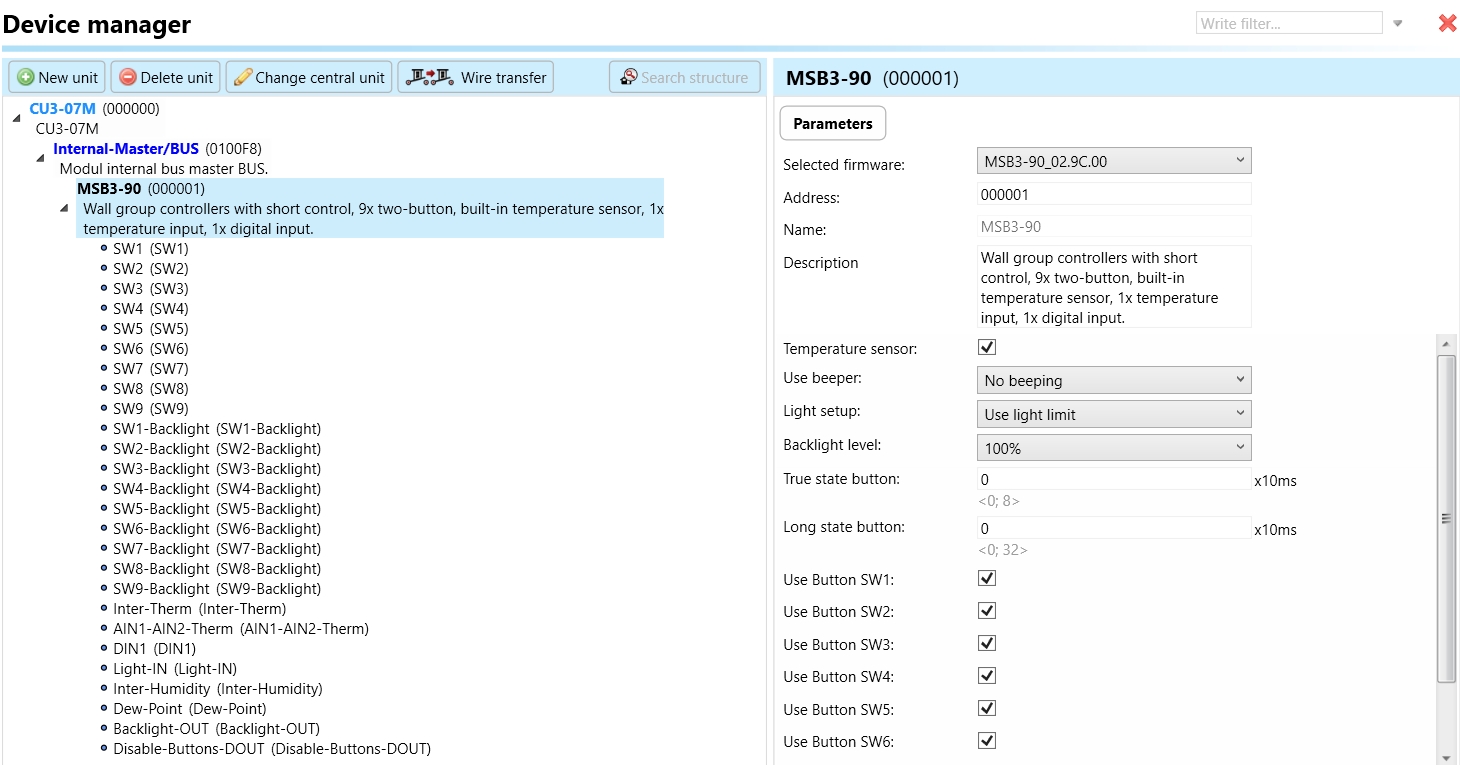

Parameters:

Parameters in the iNELS devices refer to the measurable factors or characteristics that define the behavior or performance of the device. These could include electrical properties, physical dimensions, environmental conditions, and various other specifications depending on the type of device.

These are settings specific to individual devices within our automation system.The specific parameters of the MSB3-XX/XX in the iDM as shown in Fig.2

Clicking on the MSB3-90 (Fig.2), will navigate to the selected firmware, unit address, name, and description, along with other parameters as described below.

It is important to add the device address for proper communication with the unit. The Hexadecimal device address can be find from the device.

Temperature sensor: A temperature sensor is a component integrated into the metal switch buttons (MSB3-40/XX, MSB3-60/XX, and MSB3-90/XX) that measures the ambient temperature in its surroundings. In this context, the metal switch buttons are equipped with an integrated temperature sensor, allowing them to detect and measure the temperature of the environment where they are installed.

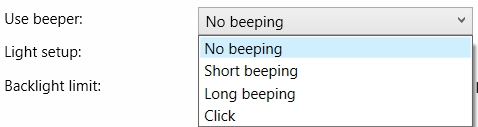

Use beeper: The "beeper" is used to emit a beeping sound to alert or notify users of a particular event or condition.

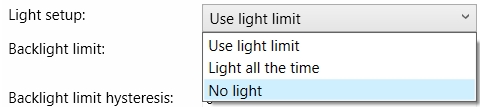

Light setup: To use the light upon preference by the user.

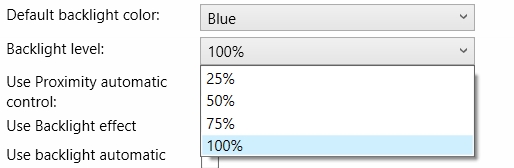

Backlight level: The backlight level refers to the intensity or brightness of the backlight used to illuminate the display. Adjusting the backlight level as shown in Fig.5 allows users to control the amount of light emitted by the display

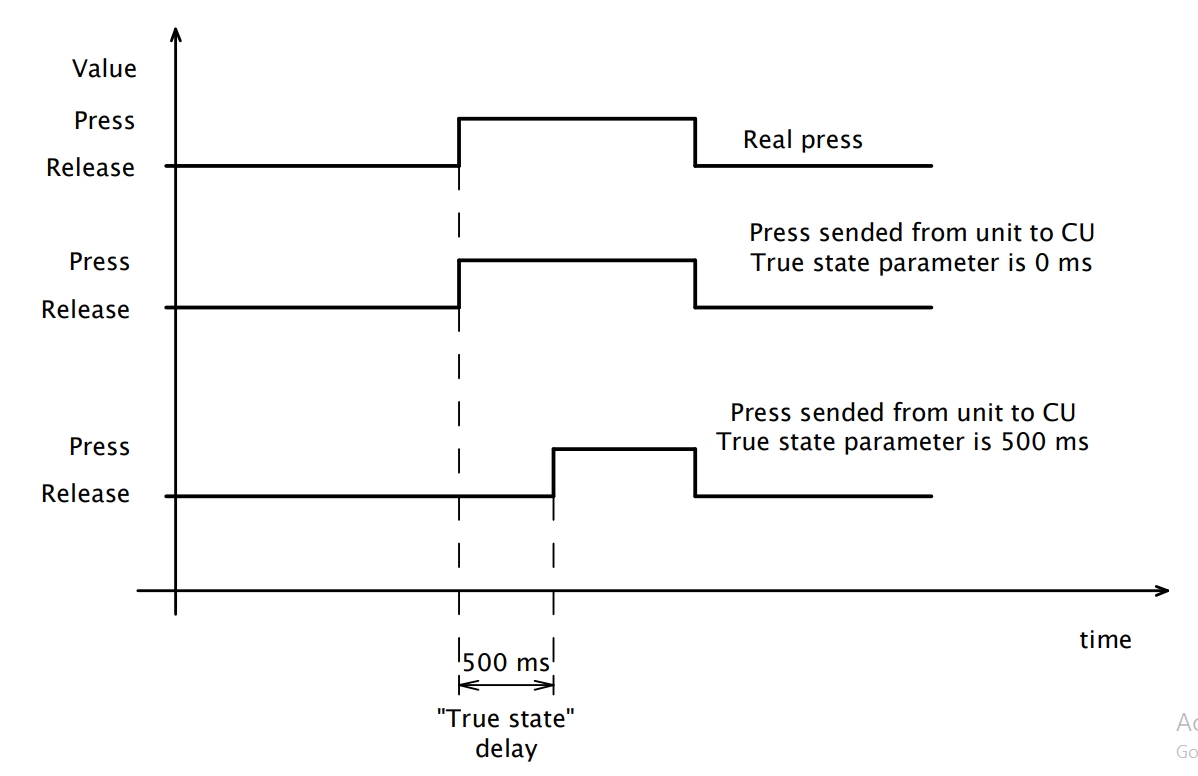

5. True state button: True state is a crucial parameter designed to address issues related to false button presses caused by interference in your system. When configured, this parameter dictates the signaling delay to the Central Unit (CU) once the button is pressed. This delay serves as a protective measure against erroneous inputs—specifically, if a false press occurs within a duration shorter than the time specified in the True State parameter, the information will not be transmitted to the CU. Consequently, the unit will intelligently disregard such short-lived signals, ensuring that only valid button presses are acknowledged and acted upon. This feature enhances the reliability and accuracy of your system, especially in environments prone to interference, offering a more robust and secure user experience.

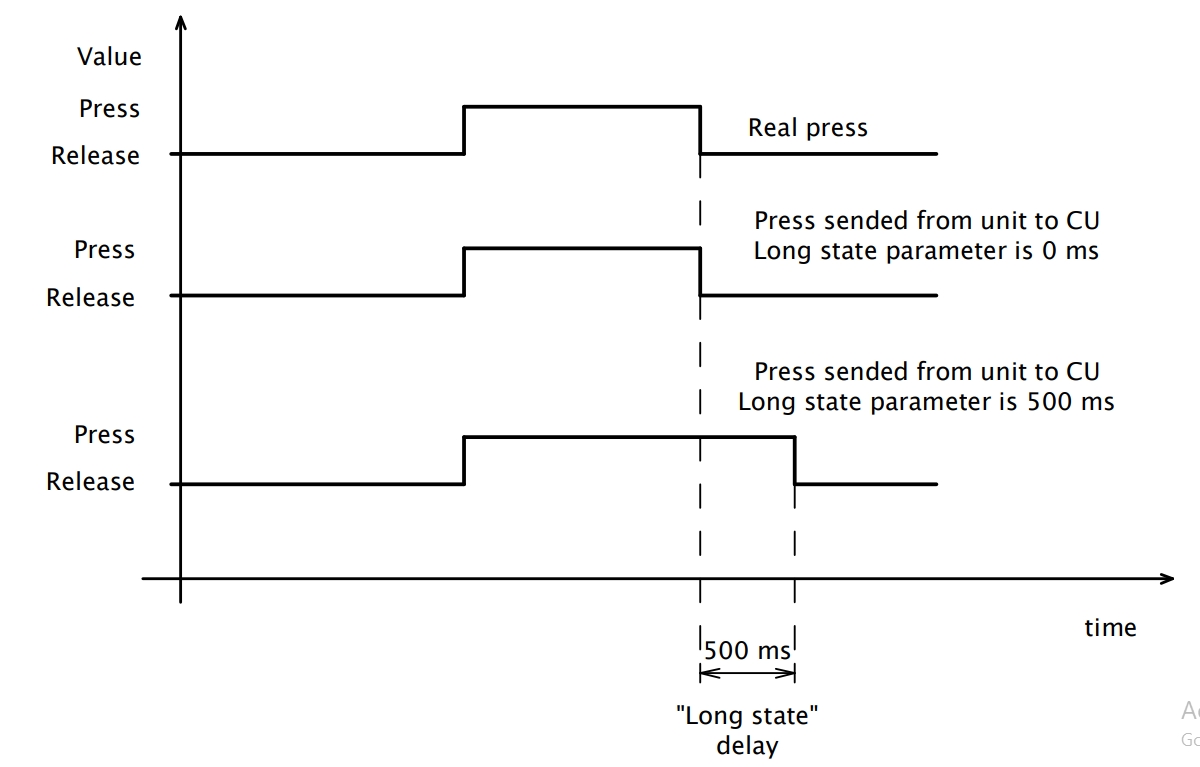

6. Long state button: Long State plays a pivotal role in mitigating challenges associated with BUS interference and slow communication in your system. Specifically, this parameter sets the signaling delay to the Central Unit (CU) when a button is released. In installations where BUS communication faces sluggishness due to interference, the Long State parameter proves invaluable.

In scenarios where a button press is short and the BUS communication is slow, there might be a risk of the unit not being able to transmit the information to the CU in a timely manner, especially regarding the acknowledgment of a press and subsequent release event. To address this concern, the Long State parameter comes into play. It extends the press time by the specified value, allowing the unit to compensate for the sluggish BUS communication. This ensures that the CU receives the necessary information regarding the button press and subsequent release, even in situations where the standard communication speed may be compromised. As a result, Long State contributes to the reliability and responsiveness of your system, offering a solution tailored to environments with BUS-related challenges.

7. Use Button SW1-SW9:A set of buttons labeled SW1 to SW9. The usage of these buttons would depend on the context in which they are implemented, such as in electronic devices, control panels, or other systems.

SW1-SW9: A "switch" could refer to a virtual or physical switch that controls a specific function within the MSB3. For example, you might have switches to control lights, heating, or other smart devices in your installation. These switches can be programmed and configured within the iNELS Design Manager to customize the behavior of your system.

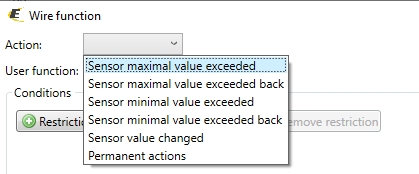

The set of actions in SW “ short press, short release, long press, long release, and permanent action can be used with various functions.

SW1-SW9 Backlight: The SW1-SW9 backlight refers to the illumination feature of individual buttons within the MSB3 series. Each touch button (SW1 through SW9) can be illuminated in white, providing visual feedback and enhancing usability, especially in low-light environments. This backlighting feature serves to indicate the status of each button, making it easier for users to identify and interact with the buttons even in dark conditions. The backlighting contributes to the aesthetic appeal of the switch buttons while also improving their functionality and user experience.

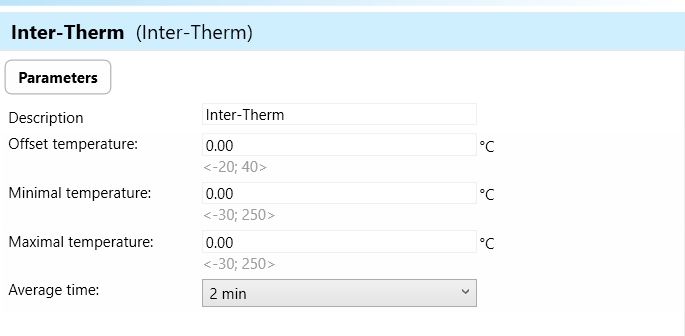

Inter-Therm: The feature that allows you to configure or monitor the temperature data from the internal temperature sensor in the MSB3. You can use this information to automate climate control, adjust heating or cooling systems, or trigger alerts based on temperature thresholds. The set of actions “Sensor maximal value exceeded, Sensor maximal value exceeded back, Sensor minimal value exceed, Sensor minimal value exceed back, Sensor value change and permanent action can be use with various functions.

Offset Temperature: Offset temperature refers to a constant value added to or subtracted from a measured temperature to account for systematic errors or discrepancies in the temperature measurement. It is used to correct or calibrate the temperature readings to ensure accuracy. In the context of MSB3, if there's a known bias or offset in the temperature sensor readings, the offset temperature parameter allows for compensating for this bias by adjusting the measured temperature accordingly.

Minimal Temperature: The minimal temperature parameter indicates the lowest temperature value that the temperature sensor integrated into the MSB3 device is capable of measuring accurately. It represents the lower limit of the temperature range within which the sensor operates reliably and provides accurate temperature readings.

Maximal Temperature: Conversely, the maximal temperature parameter denotes the highest temperature value that the temperature sensor integrated into the MSB3 device can measure accurately. It represents the upper limit of the temperature range within which the sensor operates reliably and provides accurate temperature readings without being damaged or compromised.

Average Time: Average time refer to the duration over which temperature readings are averaged to calculate a more stable or representative value. This parameter determines the time interval over which the sensor collects temperature data before computing an average value. It helps to smooth out fluctuations in temperature readings and provide a more consistent measurement over time.

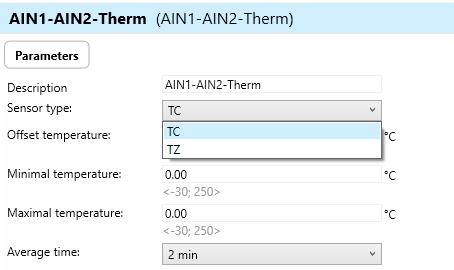

AIN1-AIN2 Therm: An analog input for temperature typically refers to a feature in a MSB3 device that can accept and process analog signals from temperature sensors. Analog signals in this context represent a continuous range of values that correspond to temperature variations. For example, a temperature sensor might output an analog voltage or current signal that changes proportionally with the temperature it's measuring. The analog input signals are converted into temperature readings. This feature allows for more precise control or monitoring of temperature within a system. It's commonly used in situations where a high level of accuracy is required for temperature-sensitive applications, such as climate control.

Sensor Type: Sensor type specifies the technology or mechanism used in the temperature sensor to measure temperature. Common sensor types include: Thermocouples: Utilize the Seebeck effect to measure temperature by generating a voltage proportional to the temperature difference between two junctions.

Offset Temperature: Offset temperature refers to a constant value added to or subtracted from a measured temperature to account for systematic errors or discrepancies in the temperature measurement. It is used to correct or calibrate the temperature readings to ensure accuracy. In the context of MSB3, if there's a known bias or offset in the temperature sensor readings, the offset temperature parameter allows for compensating for this bias by adjusting the measured temperature accordingly.

Minimal Temperature: The minimal temperature parameter indicates the lowest temperature value that the temperature sensor integrated into the MSB3 device is capable of measuring accurately. It represents the lower limit of the temperature range within which the sensor operates reliably and provides accurate temperature readings.

Maximal Temperature: Conversely, the maximal temperature parameter denotes the highest temperature value that the temperature sensor integrated into the MSB3 device can measure accurately. It represents the upper limit of the temperature range within which the sensor operates reliably and provides accurate temperature readings without being damaged or compromised.

Average Time: Average time refer to the duration over which temperature readings are averaged to calculate a more stable or representative value. This parameter determines the time interval over which the sensor collects temperature data before computing an average value. It helps to smooth out fluctuations in temperature readings and provide a more consistent measurement over time.

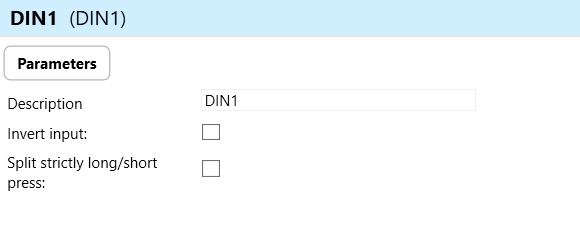

DIN1: Digital input typically refers to a feature in a MSB3 device that can accept and process binary signals, where the signal is either high (1) or low (0). Digital inputs can be used to receive signals from various sensors or devices that provide binary information. For example, a digital input could be used to connect a motion sensor or a door/window sensor. When motion is detected or a door is opened, the sensor sends a digital signal (1), and when there's no motion or the door is closed, it sends a different digital signal (0). iNELS Design Manager configures actions or responses based on the state of these digital inputs. For instance, you could set up automation rules to turn on lights when motion is detected (digital input goes to 1) or send an alert when a door is opened (digital input goes to 1).

Invert Input: "Invert input" refers to a feature that allows users to invert or reverse the logic of the digital input signal received by the MSB3 device. In other words, when the invert input feature is enabled, a logic HIGH signal (e.g., 1 or ON) at the input would be interpreted as a logic LOW signal (e.g., 0 or OFF), and vice versa. This feature provides flexibility in configuring the behavior of the digital input signal. It can be useful in scenarios where the external device or sensor connected to the MSB3 operates with an inverted logic compared to the default interpretation of the MSB3 device.

Split Strictly Long/Short Press: "Split strictly long/short press" refers to a feature that distinguishes between long and short press actions on the digital input of the MSB3 device.

Long Press: Holding the digital input signal for a predefined duration (longer than a specified threshold) before releasing it triggers a long press action.

Short Press: Briefly activating the digital input signal without holding it for the predefined duration triggers a short press action.

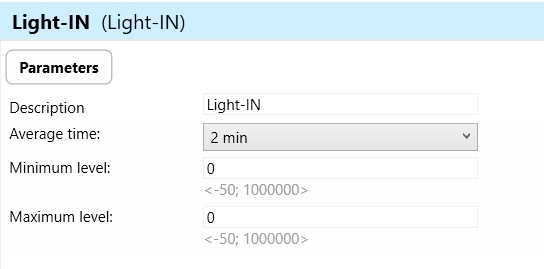

Light-IN: refers to the luminance sensor which involves the integration with lighting control systems and uses the sensor's readings to dynamically control artificial lighting sources.

Average Time: Average time refers to the duration over which the luminance sensor averages multiple readings to calculate luminance value. This parameter helps to smooth out fluctuations in light levels caused by factors such as changes in natural light, flickering, or sensor noise.

Minimum Level: Minimum level refers to the lowest luminance threshold at which the GSB3 device will activate or adjust artificial lighting sources in response to changes in light levels detected by the luminance sensor. When the measured luminance falls below the minimum level, the GSB3 device initiates appropriate actions to increase the brightness of artificial lighting sources.

Maximum Level: Maximum level refers to the highest luminance threshold at which the GSB3 device will deactivate or adjust artificial lighting sources in response to changes in light levels detected by the luminance sensor. When the measured luminance exceeds the maximum level, the MSB3 device initiates appropriate actions to decrease the brightness of artificial lighting sources.

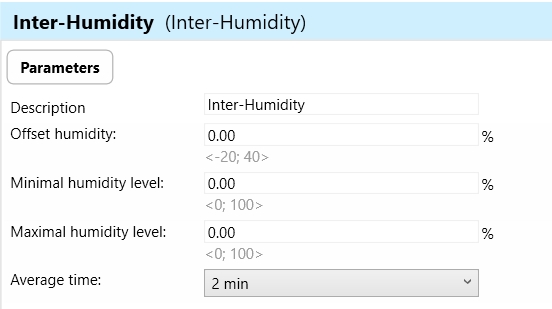

Inter-Humidity: The internal humidity sensor is a component within the MSB3 device that measures the moisture content in the surrounding environment. This sensor provides data on humidity levels, allowing the system to make informed decisions or trigger actions based on those readings. For example, if the internal humidity sensor detects high humidity levels, the system may trigger ventilation or air conditioning to maintain a comfortable environment. Set up rules or automation scenarios based on the readings from the internal humidity sensor.

Offset Temperature: Offset temperature refers to an adjustment applied to the humidity readings to compensate for temperature variations that may affect the accuracy of humidity measurements. This adjustment ensures that humidity readings remain accurate and reliable across different temperature conditions.

Minimal Humidity Level: Minimal humidity level refers to the lowest threshold at which the MSB3 device will trigger actions or responses based on changes in humidity levels detected by the humidity sensor. When the measured humidity falls below the minimal level, the MSB3 device initiates appropriate actions to maintain or increase humidity levels

Maximal Humidity Level: Maximal humidity level refers to the highest threshold at which the MSB3 device will trigger actions or responses based on changes in humidity levels detected by the humidity sensor. When the measured humidity exceeds the maximum level, the MSB3 device initiates appropriate actions to reduce or control humidity levels.

Average Time: Average time refers to the duration over which the humidity sensor integrates or averages multiple readings to calculate a representative humidity value.

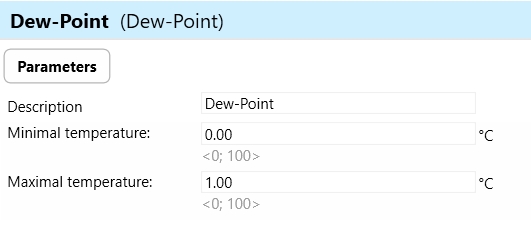

Dew-Point: The dew point is the temperature at which air becomes saturated with moisture and dew or frost begins to form. It's the point at which the air holds the maximum amount of water vapor it can, and any further cooling will result in the condensation of water vapor into liquid water or frost. In climate control system, monitoring the dew point can be important for maintaining a comfortable indoor environment and preventing issues like condensation on windows or roof surfaces.

Minimal Temperature: The minimal temperature parameter refers to the lowest temperature at which the integrated temperature sensor of the MSB3 device can accurately measure ambient temperature. This parameter is important because it defines the lower limit of the device's temperature measurement range.

Maximal Temperature of Dew-point: The maximal temperature of dew-point refers to the highest temperature at which dew point, the temperature at which air becomes saturated with moisture and dew begins to form, can occur. Dew point is influenced by both temperature and humidity, and exceeding the maximal temperature of dew point may lead to condensation or dew formation on surfaces.

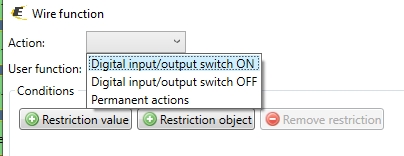

Backlight-OUT: Refers to the element related to the backlighting of all point-illuminated LED in buttons/switches on MSB3 devices. The set of actions “Digital input/output switch ON, “Digital input/output switch OFF and permanent action can be used with various functions.

Disable-Buttons-DOUT: This parameter is used for disabling buttons, preventing those buttons from triggering specific actions or functions within a system. The set of actions “Digital input/output switch ON, “Digital input/output switch OFF and permanent action can be used with various functions.

Exports for iNELS Cloud and APP

Setting Up Control and Monitoring for iNELS Cloud and iNELS App

It is possible to control and monitor all the bus units in iNELS cloud and iNELS app. There are two stages to set up this function. Stage one is to do configuration in iDM3 and stage 2 is to do Configuration in iNELS cloud page and iNELS app.

A. Configuration in iDM3.

1. Unit and Parameter Selection:

Begin by accessing the iDM3 interface on your PC connected to CU. Navigate to the Device Manager section and carefully select the units and parameters you wish to control(Fig: 1). This step is essential for determining what gets exported to the iNELS cloud and app.

Fig.1: Device Manager section

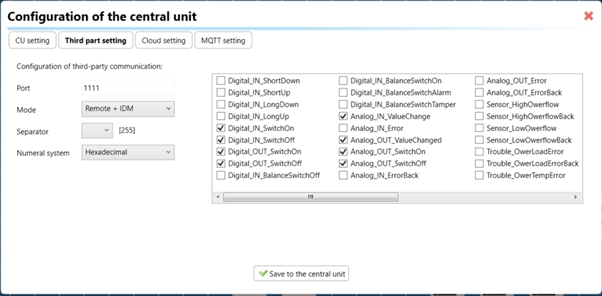

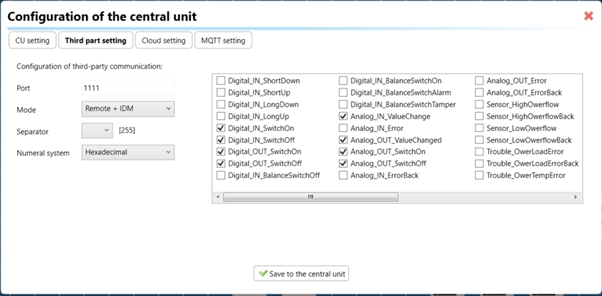

2. CU Configuration and Third-Party Settings :

After the above step, go to the CU configuration in the iDM3, and select the page for third-party settings(refer to Fig. 2).

Inside the third-party settings page, designate the port for cloud connection. Set the mode of operation and choose the numerical system as hexadecimal. Pay close attention to verifying and configuring all essential parameters for successful cloud export.

Fig. 2: Configuration of the central unit

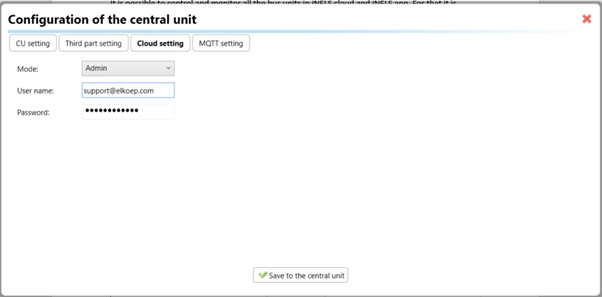

3. Cloud Settings:

Move on to the Cloud Settings section within iDM3refer to Fig. 3).

Input the details of your iNELS cloud account. If you haven't created one, utilize the "New User" tab on the iNELS Cloud web page to establish a free account. (Inels Cloud - ElkoEP).

Select the mode and input the cloud account credentials. Save the project to the central unit to generate and store the export project file in the iNELS cloud account.

Fig. 3: Configuration of the central unit

B. Configuration in iNELS cloud page and iNELS App.

1. Online Status Verification:

Once the cloud credentials and export settings in iDM3 are configured successfully, check the iNELS cloud account's Gateway section. Confirm that the Central Unit (CU) is online and that the export file has been automatically sent to the cloud under your account.

Fig. 4: Online status verification

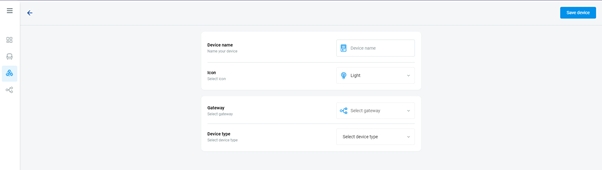

2. Device Creation in Cloud Platform:

In the cloud platform, you have to create new devices in order to control it remotely.

In the device tab, you will find the add device button, which can be used to associate export elements from IDM with the required types and icons.

Fig. 5: Device creation in cloud platform

After entering any name of the device, you select the icon, the MAC address of the communication gateway (in this case CU3), a specific type of device, and the address of a specific function and element from the iNELS BUS system.

In order to be able to use the iNELS application to control the devices from CU over the local network or the cloud, it is necessary to create a room for bus devices for each central unit and add the devices into the room.

Follow these steps meticulously to ensure a seamless configuration process for controlling and monitoring all bus units through iNELS cloud and iNELS app.

3rd Party Integration with iNELS BUS

3rd Party Integration (MQTT)

iNELS units support MQTT integration on central units CU3-07M, CU3-08M, CU3-09M, and CU3-10M. It is necessary to select the devices and parameters for 3rd party integration on the device manager in the iDM.

Please note that you have an MQTT broker (local or cloud) running in the installation for this integration.

After you have a working MQTT broker you need to configure iNELS Central units to communicate with it. If you have no knowledge of what MQTT is, you can learn about it from MQTT Essentials articles. https://www.hivemq.com/mqtt/

There is a pre-installed MQTT broker in the iNLES bridge, it can be used to connect the iNELS Central units for integration in your projects.

Configuration in iDM3: Select units of 3rd Party integration.

Unit and Parameter Selection:

Begin by accessing the iDM3 interface on your PC connected to CU. Navigate to the Device Manager section and carefully select the units and parameters you wish to control. This step is essential for determining what gets exported to the 3rd party integration via MQTT.

Fig.1: Device Manager section

2. CU Configuration and Third-Party Settings :

After the above step, go to the CU configuration in the iDM3, and select the page for third-party settings.

Inside the third-party settings page, designate the port for third-party connection. Set the mode of operation and choose the numerical system as hexadecimal. Pay close attention to verifying and configuring all essential parameters for successful third-party integration.

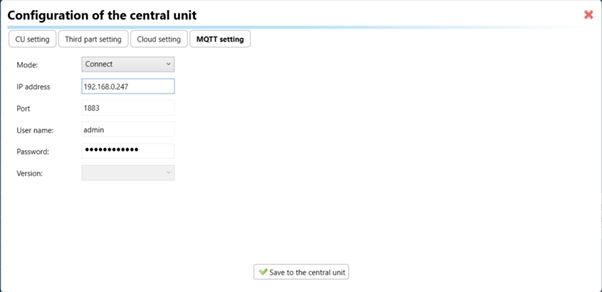

3. MQTT Settings:

Move on to the MQTT Settings section within iDM3.

Input the details of your MQTT broker.

Select the mode and input the broker credentials such as IP, port username and password. Save the project to the central unit.

MQTT payload

For MQTT payload description please refer the link below. https://wiki.inels.com/v/inels-bus/3rd-party-integration/mqtt-payload-description-of-inels-bus-devices

Appendices

Last updated