SA3-06M

Switching actuator, 6 channels

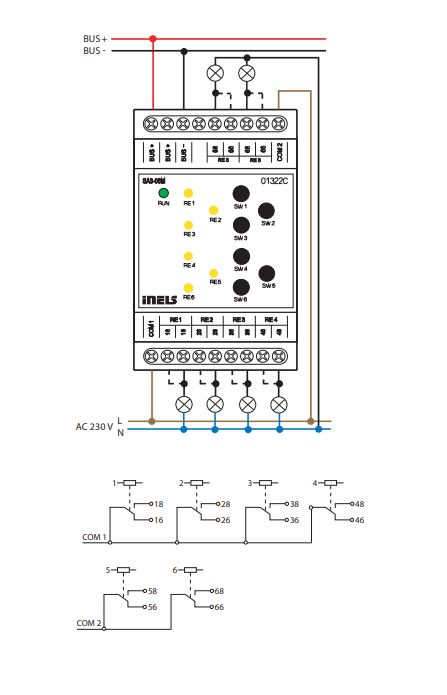

Overview of devices

An overview of the product design and usage. Includes circuit diagrams, terminal details, etc.,

Key features

The actuator SA3-06M is meticulously designed to facilitate the switching up to six diverse appliances and loads with potentialless contact. Here are the key features and specifications:

Switching Capability: SA3-06M is equipped with 6 independent relays, each incorporating changeover potentialless contacts.

Maximum Load: Each relay can handle a maximum load of 8 A/2000 VA/AC1, ensuring efficient operation for various applications.

Individual Control: The six output contacts are not only independent but also individually controllable and addressable. This provides a high degree of flexibility in managing different loads.

Relay Grouping: The relays are divided into two groups. The group of four relays located on the bottom terminal switches the common potential, while a pair of relays positioned on the top terminal switches the second common potential.

Applications: The actuator is particularly suitable for operating discontinuously controlled thermo drives in the distributor of floor heating systems.

LED Status Indicators: LEDs on the front panel serve as visual indicators, signaling the status of each output and providing quick feedback on the operational state.

Manual Control: The contact status of each relay can be changed separately and manually, using the control buttons on the front panel, offering hands-on control when needed.

Contact Material: The SA3-06M is typically supplied with AgSnO2 contact material, known for its reliability and durability.

Mounting: Designed in a 3-MODULE version, the SA3-06M is intended for convenient mounting into a switchboard/DIN rail EN60715, ensuring compatibility with standard installations.

In summary, the SA3-06M stands out for its versatile switching capabilities, individual control options, and suitability for specific applications, such as floor heating systems. The inclusion of LED indicators and manual control features enhances its usability, making it a robust choice for a variety of scenarios.

Exemplary circuit diagram/ Wiring Diagram

Compatibility chart ( CU, minimal FW version and Integration)

The chart illustrates the compatibility between switching actuators and various central units, firmware versions, and integration options.

1

CU3-01M

02.A0.00

NA

NA

2

CU3-02M

02.A0.00

NA

NA

3

CU3-07M

02.A0.00

Yes

Yes

4

CU3-08M

02.A0.00

Yes

Yes

6

CU3-09M

Preparation

Preparation

Preparation

7

CU3-10M

Preparation

Preparation

Preparation

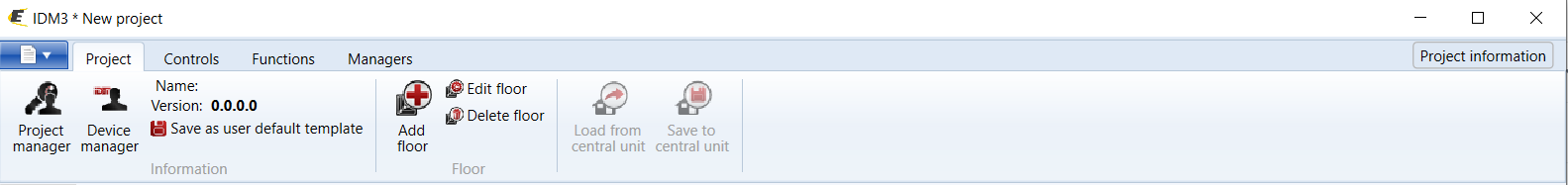

Programming in iDM

Introduction

iNELS Design Manager, or IDM3, is for programming iNELS units. This software serves as the platform for configuring device parameters, defining functions, and executing the programming required for iNELS units.

Device parameters, such as sensor range and thresholds, backlights, and operational modes, can be easily adjusted within the IDM3.

The process of programming in IDM3 typically involves defining functions and establishing logical connections between different devices. This allows for the creation of automation scenarios and the implementation of intelligent control strategies.

Starting up

Select the "blue control icon" as shown in Fig 1 > Clicking on the option "New project from default template“ allows you to create a new project from a predefined template.

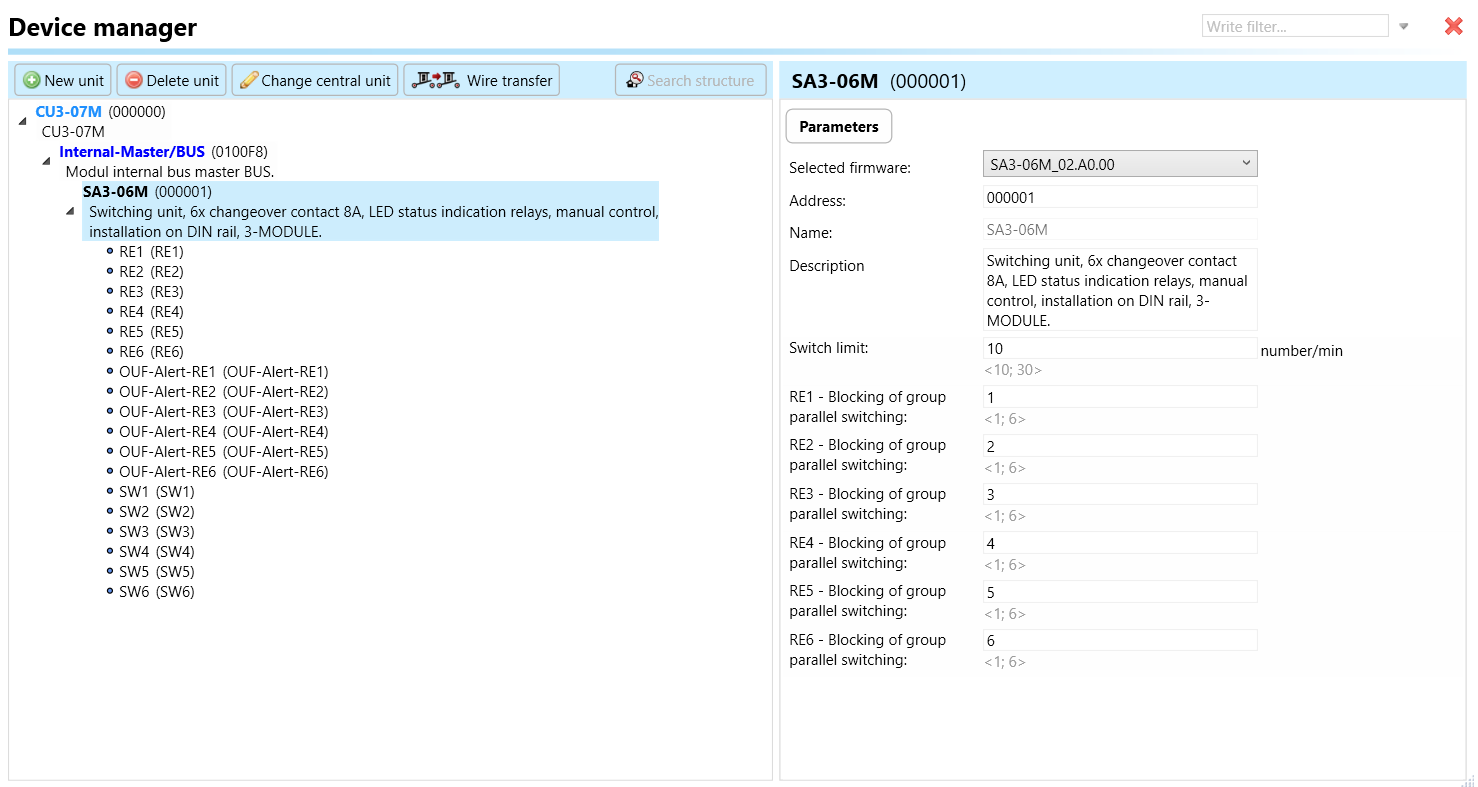

Select the "Device manager" (Fig 1)> Add "New unit "> Select the central unit > Add "New unit">Select the "Internal-Master/ BUS"> Add "New unit "> Add the devices> Click on the devices to see the "Parameters".

Parameters:

Parameters in the iNELS devices refer to the measurable factors or characteristics that define the behavior or performance of the device. These could include electrical properties, physical dimensions, environmental conditions, and various other specifications depending on the type of device.

These are settings specific to individual devices within your automation system.The specific parameters of the SA3-06M in the iDM as shown in Fig.2

Clicking on the SA3-06M (Fig.2), we can see the selected firmware, address, name, and description, along with other parameters as described below.

It is important to add the device address for proper communication with the unit. The Hexadecimal device address can be find from the device.

Switch limit:

The switch limit parameter establishes the highest allowable frequency of relay switching per minute. If the number of switch occurrences surpasses this limit within a minute, the relay will not be triggered.

RE1- RE 6 Blocking group of parallel switching:

This function is responsible for preventing or halting the simultaneous switching of a relay in parallel with other relays within the designated group. For instance, if you designate RE1, RE2, and RE3 to Blocking group of parallel switching- 1, none of these relays will switch on concurrently. This feature proves useful when connecting these relays to three distinct fans in an air conditioning system. If Fan 1 is activated, Fans 2 and 3 will not switch on in parallel, effectively safeguarding the fans from simultaneous switching.

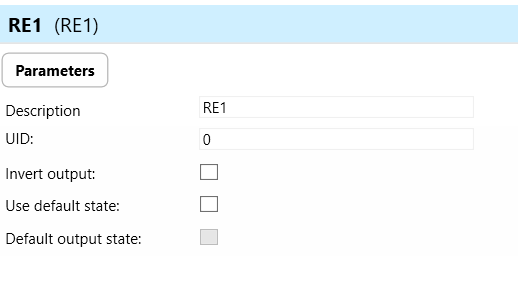

RE1- RE 6- Relays are means of remotely controlling various electrical loads, such as lights or other devices. It acts as a switch that can open or close electrical circuits, allowing or interrupting the flow of power to connected devices.

Invert output: "Invert output" refers to the ability to change the state of the output signal. When the output is inverted, a command that would normally turn the output on would instead turn it off, and vice versa.

Use default state: In the context of a switching actuator, the term "default state" pertains to the pre-established or initial condition that the actuator adopts in the absence of communication from the bus or central unit. Enabling this function ensures that the relay automatically assumes its default state, which is set to OFF.

Default output state: Upon choosing the "use default state" option, you will be prompted to specify the default output state. This refers to the pre-established or initial condition that the actuator adopts when there is no communication from the bus stop or central unit. Upon selecting this function, the relay will transition to its default output state, which, in this case, is set to ON.

OUF-Alert-RE1-OUF Alert Re 6: This parameter serves as an indicator for alert conditions associated with relay outputs 1 through 6 on the switching actuator. The alert is activated when the switching limit surpasses the configured threshold in any of the relay outputs. Upon activation, this alert signals users about a fault in one of the relay outputs, prompting them to investigate and take corrective measures. This is crucial to prevent potential damage to connected loads or the device itself. The designation "RE1-6" specifies that the alert is applicable to each relay output individually, allowing users to pinpoint the specific relay output affected by the alert.

SW1-SW 6: A "switch" could refer to a virtual or physical switch that controls a specific function within the SA3-06M. For example, you might have switches to control lights, heating, or other smart devices in your installation. These switches can be programmed and configured within the iNELS Design Manager to customize the behaviour of your system.

Exports for iNELS Cloud and APP

Setting Up Control and Monitoring for iNELS Cloud and iNELS App

It is possible to control and monitor all the bus units in iNELS cloud and iNELS app. There are two stages to set up this function. Stage one is to do configuration in iDM3 and stage 2 is to do Configuration in iNELS cloud page and iNELS app.

Configuration in iDM3.

1. Unit and Parameter Selection:

Begin by accessing the iDM3 interface on your PC connected to CU. Navigate to the Device Manager section and carefully select the units and parameters you wish to control. This step is essential for determining what gets exported to the iNELS cloud and app.

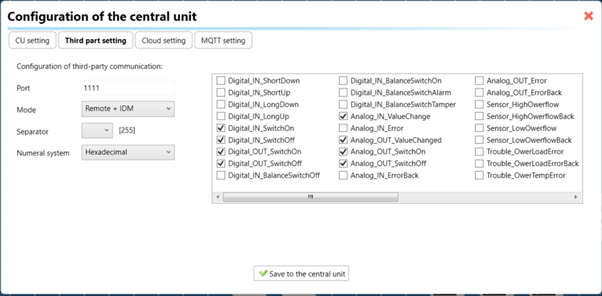

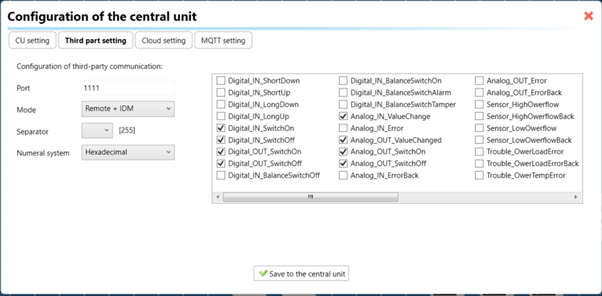

2. CU Configuration and Third-Party Settings :

After the above step, go to the CU configuration in the iDM3, and select the page for third-party settings.

Inside the third-party settings page, designate the port for cloud connection. Set the mode of operation and choose the numerical system as hexadecimal. Pay close attention to verifying and configuring all essential parameters for successful cloud export.

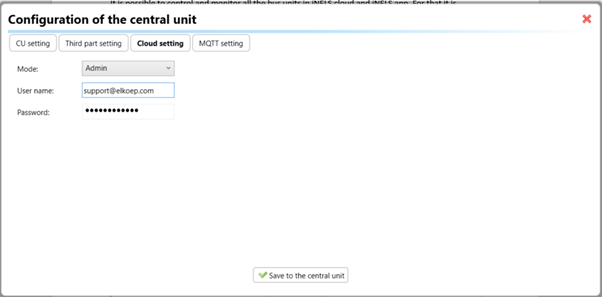

3. Cloud Settings:

Move on to the Cloud Settings section within iDM3.

Input the details of your iNELS cloud account. If you haven't created one, utilize the "New User" tab on the iNELS Cloud web page to establish a free account. (Inels Cloud - ElkoEP).

Select the mode and input the cloud account credentials. Save the project to the central unit to generate and store the export project file in the iNELS cloud account.

Configuration in iNELS cloud page and iNELS App.

1. Online Status Verification:

Once the cloud credentials and export settings in iDM3 are configured successfully, check the iNELS cloud account's Gateway section. Confirm that the Central Unit (CU) is online and that the export file has been automatically sent to the cloud under your account.

2. Device Creation in Cloud Platform:

In the cloud platform, you have to create new devices in order to control it remotely.

In the device tab, you will find the add device button, which can be used to associate export elements from IDM with the required types and icons.

After entering any name of the device, you select the icon, the MAC address of the communication gateway (in this case CU3), a specific type of device and the address of a specific function and element from the iNELS BUS system.

In order to be able to use the iNELS application to control the devices from CU over the local network or the cloud, it is necessary to create a room for bus devices for each central unit and add the devices into the room.

Follow these steps meticulously to ensure a seamless configuration process for controlling and monitoring all bus units through iNELS cloud and iNELS app.

3rd Party Integration with iNELS BUS

3rd Party Integration (MQTT)

iNELS units support MQTT integration on central units CU3-07M, CU3-08M, CU3-09M, and CU3-10M. It is necessary to select the devices and parameters for 3rd party integration on the device manager in the iDM.

Please note that you have an MQTT broker (local or cloud) running in the installation for this integration.

After you have a working MQTT broker you need to configure iNELS Central units to communicate with it. If you have no knowledge of what MQTT is, you can learn about it from MQTT Essentials articles. https://www.hivemq.com/mqtt/

There is a pre-installed MQTT broker in the iNLES bridge, it can be used to connect the iNELS Central units for integration in your projects.

Configuration in iDM3: Select units of 3rd Party integration.

Unit and Parameter Selection:

Begin by accessing the iDM3 interface on your PC connected to CU. Navigate to the Device Manager section and carefully select the units and parameters you wish to control. This step is essential for determining what gets exported to the 3rd party integration via MQTT.

2. CU Configuration and Third-Party Settings :

After the above step, go to the CU configuration in the iDM3, and select the page for third party settings.

Inside the third-party settings page, designate the port for third-party connection. Set the mode of operation and choose the numerical system as hexadecimal. Pay close attention to verifying and configuring all essential parameters for successful third-party integration.

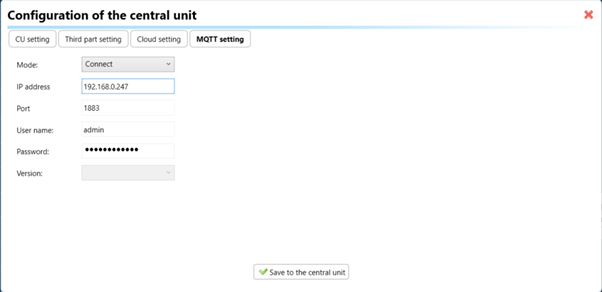

3. MQTT Settings:

Move on to the MQTT Settings section within iDM3.

Input the details of your MQTT broker.

Select the mode and input the broker credentials such as IP, port username and password. Save the project to the central unit.

MQTT payload

For MQTT payload description please refer the link below. https://wiki.inels.com/v/inels-bus/3rd-party-integration/mqtt-payload-description-of-inels-bus-devices

Appendices

Provide any optional, supplementary information that may help in providing a more comprehensive understanding of the product feature

Last updated